Solid Wood Furniture

Wood Mold Industry

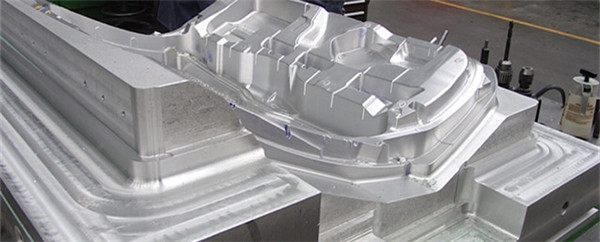

Aluminum Mold Industry

Composite Material

ABC Rubber,Plastic

Bathroom Industry

Stone Industry

Artware

Foam Mold

Special Material